ABB and CERN – Innovation partnership for reducing energy consumption

ABB

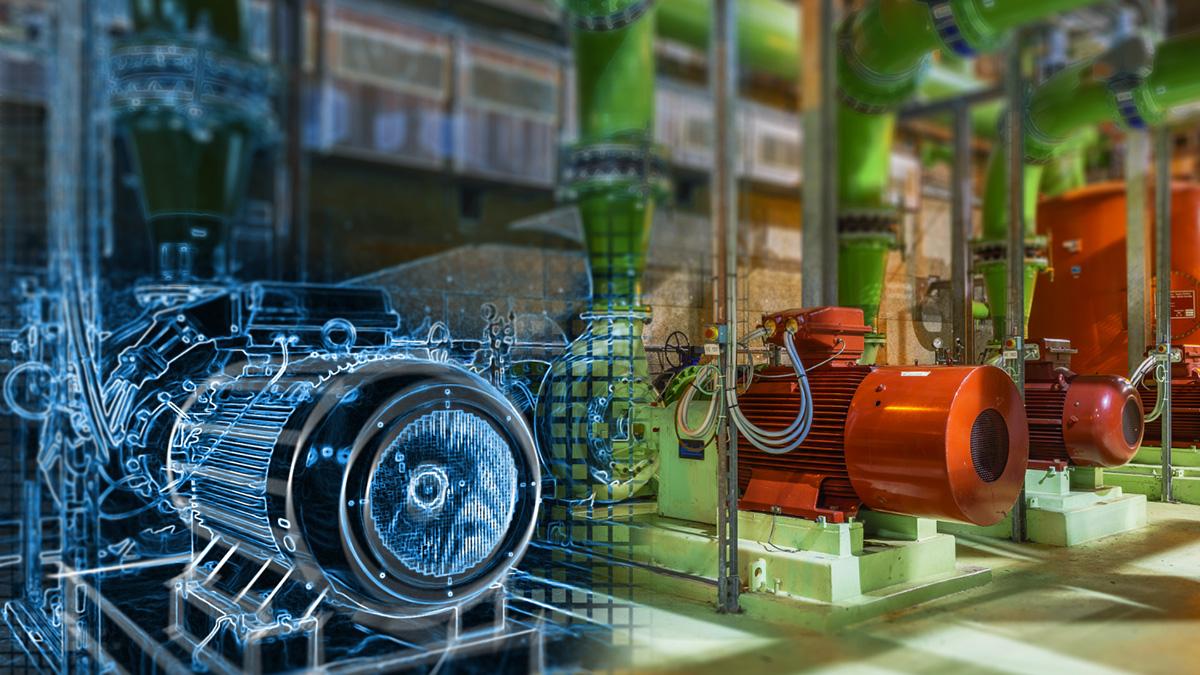

ABB, a technology leader in electrification and automation, and CERN have developed a roadmap for reducing energy consumption in the cooling and ventilation systems used in CERN's accelerator complex, experimental areas, and data centres.

“It’s an excellent example of collaboration where each side brings its own contribution to the table.”

Potential for improvement in energy efficiency

CERN and ABB experts assessed a wide variety of data from motors in various cooling and ventilation applications. They combined data from multiple sources and analysed the efficiency of the whole system to pinpoint the motors that present the best business case for energy efficiency upgrades.

The project goal was to improve energy efficiency by 10-15%, but this figure was exceeded, and the potential savings are now estimated at 17.4% across a total of 800 motors, equivalent to energy consumption in more than 18,000 European households. According to IEA (International Energy Agency), there are 300 million industrial motors in operation, which indicates enormous potential for reducing energy consumption on a large scale.

Input from both sides

This joint research project illustrates the benefits of knowledge transfer.

“It’s an excellent example of collaboration where each side brings its own contribution to the table,” says Giovanni Anelli, Head of CERN's Knowledge Transfer group. “CERN brings its large-scale infrastructure and ABB contributes with its technology and service expertise.”

Erich Labuda, President of the Motion Services division at ABB, is also pleased with the collaboration.

“As an institution with a large base of motors installed, working with CERN is a great example of how we can support in making a big impact in improving energy efficiency as part of the transition to a low-carbon society.”

Systems often overdesigned

Why was the cooling and ventilation system chosen for this research project?

“These systems are often overdesigned, being specified to operate at a maximum load way above the average,” explains Erich Labuda.

“In fact, we found one pump motor at CERN with an energy-saving potential of 64 percent. It is also important to not just evaluate motor efficiency but the system as a whole – including the fans, condensers, and cooling towers. This holistic approach supports the improvement of CERN’s overall energy efficiency and reliability.”